PCB Assembly

Have a question about our service?

Are you ready to work with us?

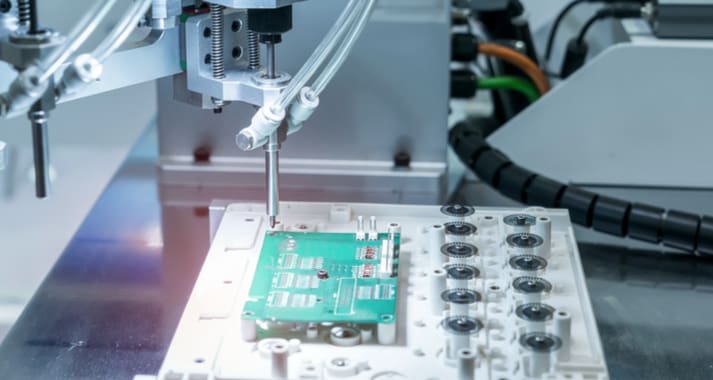

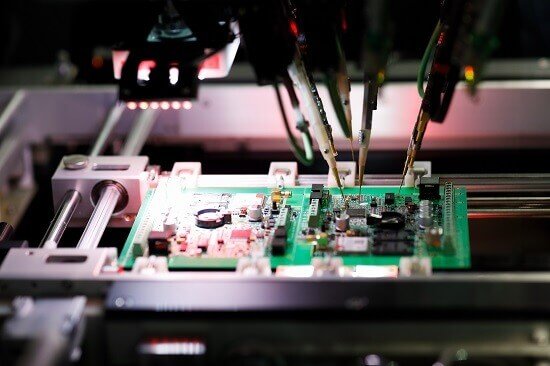

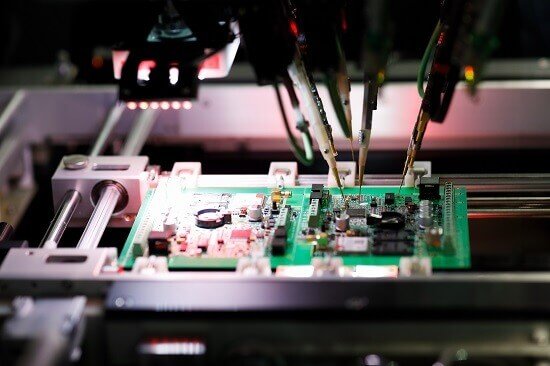

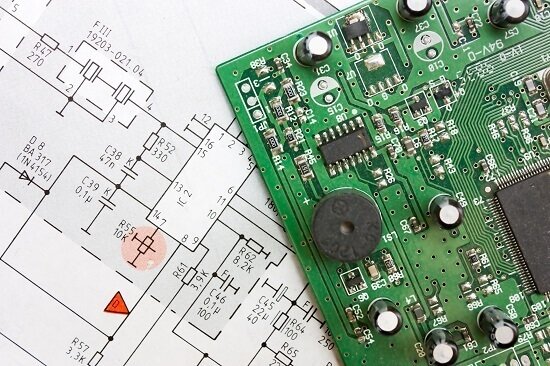

PCB assembly servicesPrinted circuit board assembly, or PCB assembly, is a process of mounting electronic components onto the PCB to make it a PCBA, which is a module that can further assemble with other parts to be an end product or system.

PCB assembly services are also known as electronic assembly services, circuit board assembly services, or circuit card assembly services.

Reviews From Customers

"Gold fingers are a line of hard gold plating pads at the edges of PCBs and are used for inserting into a connector or interface to connect the PCB with a module or system. PCBONLINE can handle gold finger PCBs independently because it has licenses to buy and use gold salt and equipment to deal with the sewage after the hard gold plating process."

This is a high-thermal dissipation PCB manufactured by PCBONLINE. Its substrate is FR4 with copper inlay. This PCB is used in an air-conditioning central system. Its copper and FR4 hybrid substrate makes a fantastic solution to thermal management but increases the PCB fabrication complexity. Our client found us, a complex PCB manufacturer. And we finished this project perfectly without return work

This is a special MCPCB manufactured by PCBONLINE. It is an aluminum substrate, but it is flexible. You may wonder that such a special PCB can be costly, but not at all, the price of flexible aluminum PCBs is as low as rigid aluminum PCBs. Flexible aluminum PCBs are mainly used for LED lights that illuminate all around. The power of the PCB is 1W, and its surface finish is OSP.

"This is an industrial control mainboard PCBA project manufactured by PCBONLINE. Our business department and the production department cooperated vigorously to ensure the quality and delivery time of this industrial PCB assembly order. Our customer praised our soldering level of 01005 surface-mount devices and expressed satisfaction with the cooperation."

PCBA Service

Finally A Technology Solution

For All Of Your Groups

MATERIALS

EQUIPMENT

TEAM

The professionals at PCBONLINE provide one-on-one engineering support, and free DFM, DFT, and DFX. And we can get into two-shift work for expedited orders.

QUALITY

ensures the best quality of PCB assembly through complete tests, including AOI, X-ray inspection, and functional testing. And it has the first article test before bulk PCB assembly.

One-Stop PCB Assembly Services |

PCBA EMS Manufacturing

Best Performance

Creative Design

We Are Provide Best Services

For Your Business!

PCB fabrication

provides PCB manufacturing of any kind from prototypes to bulk fabrication, such as FR4, flexible, rigid-flex, ceramic, MCPCBs, etc. All you need is to send your Gerber.

SMT (surface-mount technology) assembly

THT (through-hole technology) assembly

SMT is an automatic PCB assembly process. It includes solder paste printing, SPI (solder paste inspection), placing SMDs, x-ray inspection, visual inspection, reflow soldering, and AOI (automatic optical inspection).

FAI (first article inspection)

THT is a half-auto PCB assembly process. The THT components are inserted through holes by hand or machine, and then the PCBA is preheated and wave-soldered. At PCBONLINE, we use the German Ersa selective wave soldering machines to ensure soldering quality.

Functional testing

offers the FAI for PCB assembly. We manufacture 5 PCBAs and randomly pick up 1 piece to inspect every component on it. After tha

Value-added services

This is a power-on self-test. The PCBAs are put on a jig one by one to test their functionalities. At DYX , the functional test is only $0.075 per piece and is free for massive PCBA manufacturing.

Pricing Plan For Your Business

Flexible Pricing Plans!

In the PCB post-assembly stage, DYX provides complete value-added services until you receive finished products, including

Best Perfomance

PCBAs are coated with urethane/polyurethane to protect the boards from dust, moisture, chemical, vibration, and high temperatures and lengthen the lifespan.

Secure Multi Usable

IC programming means downloading a program into the ICs

Frequently Asked Questions

PCB fabrication is the process of preparing bare boards into a form or structure as per design files and specifications; and making them ready to assemble.

Yes, we run the PCB fab production with consideration of capabilities and technical expertise.

Yes, based on customers’ request; we provide solder samples.

Yes, we provide test certificates with boards based on request.

Yes, we give COC (Certificate of Conformance) with packing slip (Based on request).